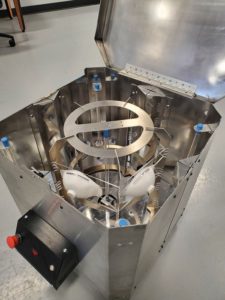

As a result of the COVID-19 pandemic, there’s an increased need for respiratory masks and a decrease in resources available, particularly in more isolated areas. In response to this problem, researchers at Camosun Innovates (CI) have developed a small, portable ultraviolet-C (UV-C) sterilization device that will allow disposable N95 face masks to be reused. The prototype can sterilize 10 masks within 30 minutes.

CI director Richard Gale says that UV sterilization technology has been around for years, but it’s never before been portable. (CI also recently developed a new face-shield design to help prevent the spread of COVID-19.)

“Most of [the technology] tends to be fairly large scale, entire rooms that are devoted to sterilization with UV-C, but what we’ve done is we’ve tried to create something completely new, a portable UV mask sterilization process,” he says.

The portable UV oven, which Camosun has called the “UVen,” uses shortwave UV-C light to break down microorganisms on a cellular level, interrupting their ability to function. It kills viral and bacterial pathogens, but doesn’t remove materials such as body fluids or dirt and grime. Gale says UV-C was the better choice compared to hydrogen peroxide vapour because it’s low-cost, requires no additional materials, and is safer for users and the environment. The UVen project is a not-for-profit endeavour; anyone may build the device without paying licensing fees.

“The whole point of the research project was to design something that would be open source, so once we’ve gone through prototyping and testing, we’re going to make the design available for free,” says Gale. “We’ll have a local manufacturer who’ll be able to respond to the needs of Island Health, and that’ll just be a charge for manufacturing the unit, but for anyone else who wants to build it anywhere else in the world, they just have to take the specs and make it happen.”

Gale says that one of CI’s priorities is to focus on solutions that have wide applicability and can be used long-term.

“Camosun Innovates really doesn’t want to focus on one-offs—we want to focus on something that’s going to have a really wide usage, something that’s really going to help not only people in BC and Canada, but people around the world,” he says. “It’s also available for doctor’s offices if they have a lot of patient need, or the big push for us was if you’re living in a residential community, on reserve, or in an isolated area where getting new masks is really hard, for places like that, it’s a real godsend.”

Gale says that keeping the cost of the UVen units low is important.

“Right now we’re dedicated to keeping the cost below $1,000 per unit; we’re using only materials that are readily available and can be found quite easily and inexpensively, and we’re trying to make the process as cheap as possible,” he says. “We hope that we’re going to get that price down closer to $750, and if it’s picked up by large-scale manufacturing, they’ll be able to drop the price considerably.”