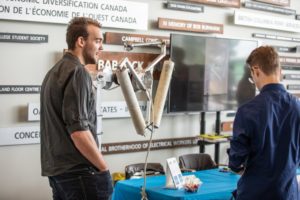

Four Camosun students were recently recognized for their work for a local seaweed company with the Most Innovative Project award at the college’s 2021 Mechanical Engineering Student Showcase. For their capstone project, Mechanical Engineering students Anika Andersen, Marshel Glidden, Justin Tomlinson, and Huu Duong Nguyen worked with Sidney’s Cascadia Seaweed to develop a kelp seed launcher to assist in the seeding of seaweed.

“It definitely made it challenging meeting with the groups and getting into the swing of things [because of COVID-19],” says Anderson, “but I would say that we also found new ways to make things work. I feel like we still worked well as a team and it was obviously helpful when we were able to be on campus working as a group, although we couldn’t have as late of nights as in previous years.”

“I would say the biggest impact COVID had was more on the academic side and less to do with the capstone itself,” adds Gidden. “For the most part, what we ended up doing during the capstone, I guess for the first month or so we had to do everything remotely, but once we got on campus, which started in probably May, and we started seeing each other regularly, from there, for me, it didn’t really factor, we were just kind of working together and it wasn’t that big of an impact.”

To create what they call the Kelp Seed Launcher V2.0, the students had to deal with an elaborate process that involved a lot of tricky detail work.

“The method that they use for growing seaweed is that they have a thin string and they wrap it around a large rope, and the thin string is what carries the seeds, so they wrap the string around the rope and they leave it in the ocean, and that’s how they grow their seaweed,” says Glidden. “They were looking to just kind of streamline the process of getting that string wrapped around the main rope and that’s where we started. There were a bunch of restrictions on what we were able to do because of the fragility of the seeds that were on the string line, the seed line, so there were a lot of little intricate problems to solve around not touching the string line and things like that.”

“We had to tension the seed line without contact to it,” adds Andersen, “so that’s where we came up with a design that ended up spinning the spools, which were also a fixed dimension, and those could spin, as well as the spindle spinning around the rope, and we put three of those on the pump launcher 2.0 so they could do an entire 250-metre run in one go without having to stop and retie lines and everything, which takes them a lot of time and they drift into adjacent lines and they can ruin other, already seeded, lines.”

Andersen says seaweed is a really great crop, it doesn’t require a lot of resources—just some clean ocean water in a protected cove—and it helps sea life.

“It can help clean up the ocean,” says Andersen. “It’s used in so many things, from food and beauty products, it can even be used for something like a biofuel cell, and with our expanding population having something like this that can actually help with food and fuel needs in the future, that’s pretty awesome.”

The end result of the students’ project is that it streamlines the process for Cascadia.

“This operation that used to take them probably 15, 20 minutes to get from one end to the other because all of the cutting and tying of rope that they had to do,” says Glidden, “is theoretically reduced to about five minutes, where they don’t have to do any cutting and tying, they can just take off from one side and switch through the spools as they need without cutting any of their main production line.”