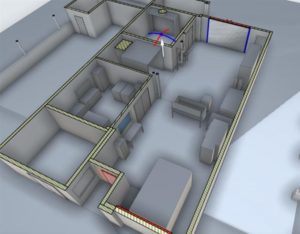

Camosun College is in the process of getting its Miracle—which stands for “materials, integration, research and creativity”—lab ready. At 3,600 square feet, it’s expected to be open in March of this year at the college’s Interurban campus, adjacent to the Jack White Building. In the lab, students will make materials into carbon fibre; the result is a very strong and light material, commonly used in airplane, ship, and car design.

The costs of the lab—which total about $2.4 million—will be split three ways between the Canadian Foundation for Innovation (CFI), the BC Knowledge Development Fund (BCKDF), and Camosun, with CFI and BCKDF taking on 40 percent each, and Camosun footing the remaining 20 percent.

Camosun Innovates director Richard Gale says the whole idea behind the lab stemmed from industry need.

“We were having businesses, companies, coming to us that really had a need for advanced manufacturing techniques around carbon fibre and composites, generally, that would withstand more stress than they were able to accommodate through other standard means,” he says. “It was less about our wanting to hit the cutting edge and more about us trying to really respond to the needs of those that are around us.”

Gale says that there’s really no single material that provides both strength and flexibility so it makes sense to combine materials. He points to an example: creating a seat for a Paralympic sledge-hockey athlete. The seat could be 3D printed, but it likely wouldn’t last long because it would be so brittle and have large gaps, as is common with 3D printing. Plastic or metal is strong enough but not comfortable enough, says Gale.

“What we need is something that’s going to be not just strong enough to withstand the impact, but also flexible enough to maintain comfort and stability for the human body,” he says.

Gale says there is “certainly an issue” around the safety of students and workers in the space, given that working with composites leads to toxins as a result of off-gassing. But, he says, the issue of safety is always present in manufacturing, and he says one of the reasons the college is so happy to have the funding to create the lab is to have the money to be able to make sure the lab is safe.

“It’s going to be environmentally controlled; it’s going to have the kinds of controls that we need to make sure that the work is done in the safest possible way. Every form of manufacturing has this kind of safety concern in place, and one of the nice things about doing this at Camosun is that, rather than working in a warehouse, you’ll be working in a smaller space that enables you to really kind of get your hands dirty without having a substantial risk.”

Gale says that in the future the fields of automation and robotics will help to augment the manufacturing process.

“Although we really are trying to serve the community, and to serve the needs of business on the island, this is a huge step forward for students at Camosun,” he says. “To be able to do this kind of hands-on learning is going to make them even more valuable once they hit the marketplace.”